Slow-Speed, High-Torque Industrial Shredders for Waste, Wood, and C&D

Designed to power through C&D debris, wood waste, and MSW—even in Talk To An ExpertSlow-Speed, High-Torque Industrial Shredders for Waste, Wood, and C&D

Built for the dirtiest, toughest jobs — Foreman Equipment’s slow-speed, high-torque industrial shredders crush through concrete with rebar, mattress springs, wet wood waste, and more. Whether you’re tackling municipal solid waste (MSW), land clearing debris, or construction and demolition (C&D) material, these machines are made to deliver.

🦾 Heavy-Duty Performance

Crushes rock and concrete with ease. Rebar? No Problem.

♻️ Multi-Waste Versatility

Handle Concrete, MSW, Wood Waste, Green Waste, Mattresses and tires in one machine.

⚙️ Precision Power

Low-speed, High-Torque shredders equal less downtime and more productivity.

🚛 Maximize Throughput

Keep material moving, even the bulky gnarly tangled stuff.

🛠️ Low Maintenance, High Uptime

Easy access, maintenance and service points.

👷♂️ Backed by Foreman

Parts, service, and support from people that know the job.

Why These Shredders Matter

Why These Shredders Matter

Slow-speed, high-torque shredders are essential across waste management, recycling, construction and demolition (C&D), agriculture, forestry, and land management. They’re designed to handle an incredibly wide range of waste materials while reducing environmental impact and maximizing operational efficiency.

At-a-Glance: Why Choose a Slow-Speed Shredder?

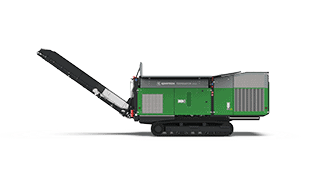

Mobile Shredders: Flexibility Meets Power

Set Up Fast. Move with Ease.

Mobile shredders are compact, self-contained, and ready to roll. Load them onto a low-bed trailer and move them directly to the job site — no need for site prep or large crews.

One Pass, Consistent, High-Quality Output

These shredders are known for producing a uniform, high-quality end product. The combination of low rotor speed and high torque ensures efficient size reduction—even for the most challenging materials—in a single pass. This results in:

- Consistent shred sizes

- Lower fuel consumption

- Reduced wear and tear

Versatility That Pays Off

Mobile slow-speed shredders can process:

- C&D waste

- MSW

- Single-stream recycling

- Organics

- Wood and green waste

Whether you’re clearing land, recycling demolition debris, or processing municipal solid waste, these machines deliver.

Uniform Consistency

How do mobile slow-speed shredders achieve uniformity in shred size and what are their advantages in terms of energy efficiency, downtime reduction, material versatility, easy mobility, and safety?

Consistent Shred Size

Mobile slow-speed shredders deliver uniform and consistent shred sizes by leveraging a slow rotor speed and high torque. This allows for comprehensive shredding, breaking the material into smaller, more even pieces. Various cutting tools like knives and sieves are used to further refine the material. A screening process is often included to ensure the end product meets specific requirements.

Energy-Saving

Compared to stationary shredders, mobile slow-speed variants are more energy-efficient. Their design, which combines low rotor speed with high torque, minimizes energy use while maintaining product quality. Most modern machine designs feature meticulous engineering, quality materials and components; these shredders are durable and require minimal maintenance, enhancing cost-efficiency and energy savings.

When used independently, shredders are highly effective in reducing the size of various waste materials and transforming bulky items into manageable pieces for easier disposal or further processing. Alternatively, they can act as the first stage in a comprehensive recycling process, breaking down waste into smaller sizes more suitable for subsequent sorting, separation, and material recovery. Whether functioning as standalone units or as part of a multi-step recycling chain, shredders are indispensable in optimizing waste management and promoting a more sustainable approach to resource utilization.

Why Uniform Consistency Matters

Precision Shredding

These machines achieve uniform shred sizes using a slow rotor speed and high torque. Paired with cutting tools and integrated screens, the material is reduced evenly and efficiently. The result? Higher-quality output ready for composting, reuse, or further material recovery.

Energy Efficiency

Thanks to their mechanical design, mobile shredders use less energy while producing excellent results. With fewer moving parts and rugged components, they also require minimal maintenance—maximizing uptime and minimizing operating costs.

Shredders at the Core of a Greener Operation

Standalone or System-Integrated

Industrial shredders can function as standalone units or as part of a multi-stage recycling system. In both cases, they:

- Reduce bulky waste for easier handling

- Prepare material for downstream separation

- Improve efficiency of waste processing facilities

Whether you’re managing a small-volume operation or a complex recycling stream, shredders form a critical first step.

Real Business Benefits

Recover High-Value Commodities

Shredders help recover valuable materials like:

- Ferrous & non-ferrous metals

- Plastics

- Organics

This boosts your revenue stream and supports a circular economy.

Slash Landfill & Disposal Fees

On-site shredding of wood and green waste reduces landfill volume and cost. Shredded materials can be reused directly as mulch, compost, or erosion control, saving:

- Transport costs

- Tipping fees

- Labour hours

Cut Fuel, Labour & Transport Costs

By managing waste on-site, mobile shredders eliminate the need to haul bulky material off-site. This translates to substantial savings across fuel, transportation, and labour, while reducing your carbon footprint.

Built for B.C. Applications

Land Clearing and Site Cleanup

CRAMBO dual-shaft, slow-speed shredders shine in land clearing. They easily process oversized wood, stumps, and green waste, prepping material for composting or reuse.

Construction and Demolition (C&D) Waste

From wood and concrete to plastics and metals, the Evoquip Caiman 150 simplifies C&D and waste recycling by enabling cross-stream processing.

MSW and Organics Recycling and Disposal

Perfect for municipalities and transfer stations, slow-speed shredders handle a diverse range of waste—organic materials, plastics, packaging, and more.

Learn more about our shredder models.

CRAMBO

Dual-Shaft

TERMINATOR

Single-Shaft

CAIMAN 150

Compact

Ready to raise your operation to the next level.

Learn more about Crambo Dual-Shaft, Slow-speed mobile shredders

Why These Shredders Matter

Why These Shredders Matter