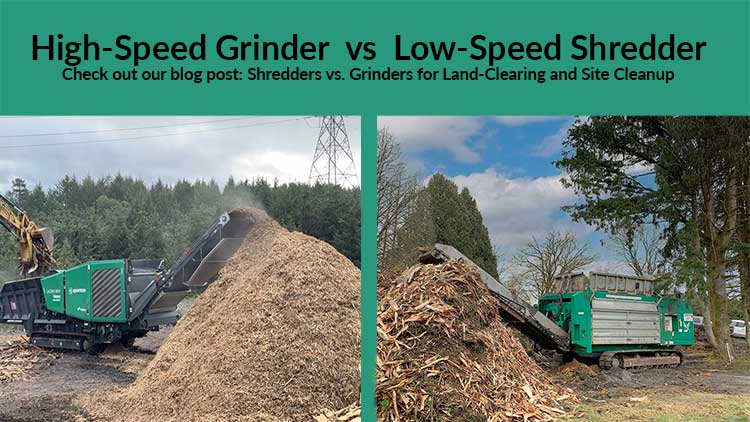

Komptech Lacero 8010 Wood Grinder

Ready to tackle your most demanding jobs.The Lacero powers through logs, green or wood waste, or land-clearing debris with ease!

Eco-Friendly Waste Management with the Komptech Lacero 8010

Eco-Friendly Waste Management with the Komptech Lacero 8010

The Komptech Lacero 8010 is a high-speed horizontal grinder designed to meet the diverse waste processing needs of North America. With its robust build and high production capacity, this machine excels in handling wood waste, biomass, mulch, and organic waste. It plays a vital role in sustainable waste management, transforming waste into reusable materials and promoting environmental conservation by reducing landfill contributions and enabling recycling.

Effortless Processing of Various Materials

The Lacero 8010 efficiently grinds large volumes of:

- Green waste

- Wood waste

- Logs

- Spools

- Land clearing debris

Its open-front hopper design with a versatile loading height of 7’10” makes material access and handling easy and efficient. Contractors benefit from faster loading times and reduced operational strain, enhancing productivity in every cycle.

Powerful and Efficient Grinding

The Lacero 8010 delivers exceptional grinding performance, thanks to its:

- CAT® C18 engine, capable of generating 812 HP for demanding tasks.

- 41″ diameter downswing drum with 16 carbide-coated teeth, ensuring optimal grinding efficiency and durability.

Clean, High-Quality Output

The result is a high-quality end product that meets the standards of demanding applications across various industries

The Lacero 8010 produces clean and consistent output materials, ideal for repurposing as mulch, biomass, or other valuable products. This is achieved through:

- Advanced metal detection systems that remove contaminants.

- Additional contamination protection features ensuring the integrity of processed materials.

The result is a high-quality end product that meets the standards of demanding applications across various industries

.

Quick Facts

- Efficiently feed large volumes of green waste, wood waste, stumps, railroad ties, spools, and land-clearing debris into the open-front hopper with a versatile 7’10” loading height

- Leverage all-day grinding production with the 41″ diameter, downswing drum with 16 carbide-coated teeth powered by a CAT® C18 engine and PT Tech clutch

- Produce clean, consistent output material product thanks to the metal detection system with additional contamination protection

Features

- Spacious Material Infeed Table:

- 13’10” length with a capacity exceeding 6.5 cubic yards.

- High-Performance Drum:

- A 41.3″ diameter, 3.5-ton downswing drum with 16 carbide-coated teeth for consistent grinding.

- Powerful Engine:

- CAT® C18 engine with a maintenance-free PT Tech clutch, delivering up to 812 HP.

- Contamination Protection:

- Integrated metal detection system with additional safeguards and a hydraulically swivelling screen basket.

- Mobility Options:

- Tracked chassis for site versatility and an optional three-axle dolly system for efficient on-road transportation.

Applications and Benefits

The Lacero 8010 is highly versatile and supports multiple industries, including:

- Pulp and Paper Mills: Processing wood waste into pulpable materials and producing feed material (Hog Fuel) for biomass powered plants.

- Sawmills: Managing sawmill byproducts effectively.

- Construction and Demolition (C&D): Handling debris and converting it into reusable materials.

- Municipal Solid Waste (MSW): Contributing to waste diversion and landfill reduction.

- Whole Orchard Recycling (WOR): Disposing of old unproductive trees that have reached the end of their lifecycle.

Practical Benefits:

- Cost Savings: Reduces transportation and disposal expenses by processing waste on-site.

- Increased Productivity: Designed for continuous operation with minimal downtime.

- Environmental Impact: Supports sustainable practices by promoting recycling and repurposing of waste materials.

Weights, Dimensions, Specs

Power: Diesel Engine / Horsepower CAT® C18 / 812 HP

Transport Dimensions (LxWxH): 44’4″ x 9’5″ x 12’4″ (13.5 x 2.8 x 3.7 m)

Working Dimensions (LxWxH): 52’6″ x 9’5″ x 15’3″ (16 x 2.8 x 4.7 m)

Machine Weight: ~90,000 lbs / ~102,000 lbs (with dolly system)

Feed Table Dimensions (LxWxH): 13’10” x 4’11” x 7’11” (4.2 x 1.5 x 2.4 m)

Infeed Opening Dimensions (HxW): 2’7″ x 4’11” (8 x 1.5 m)

Drum Dimensions (Diameter x Width): 41.3″ x 60.2″ (1 x 1.5 m)

Performance (dependent on material)

Maximum Drum Speed: 912 rpm

Maximum Throughput: up to ~450 yd3/hr (~344 m3/hr)

See the Komptech Lacero In Action

Talk to one of our Experts

Have you got questions or want more information.