Crush More Aggregate, Concrete and Asphalt.

Horizontal and Vertical Shat Impactors for All Stages of Crushing.

What is an impact crusher?

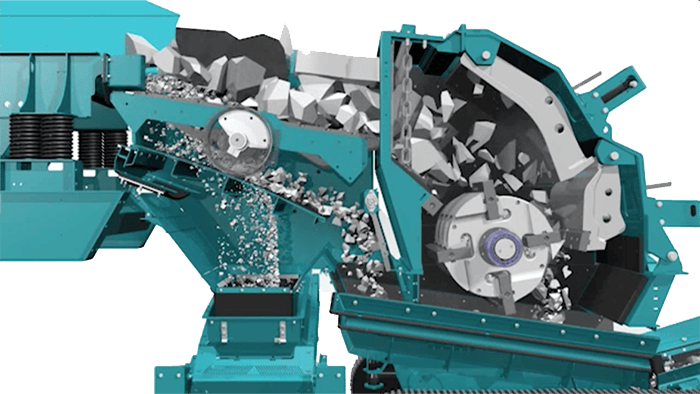

Impactors are versatile crushers used in every stage of crushing. Unlike jaw and cone crushers, which use compression to crush rock, impactors rely on velocity and impact to reduce the size of the material. Because this type of crusher doesn’t generate the same amount of force as compression crushers, it is best suited for less abrasive softer rock like limestone.

Impactors are versatile crushers used in every stage of crushing. Unlike jaw and cone crushers, which use compression to crush rock, impactors rely on velocity and impact to reduce the size of the material. Because this type of crusher doesn’t generate the same amount of force as compression crushers, it is best suited for less abrasive softer rock like limestone.

Their large feed opening and high reduction ratio also makes them well suited for crushing concrete and asphalt for recycling.

Types of Impact Crushers

There are two configurations of impact crushers: Horizontal and Vertical Shaft Impact Crushers

How Impactors Work

HSI crushers

The impact of the bars continually crushes this material until it becomes fine enough to pass through the apron plate gap, and enters the secondary crushing chamber where it is crushed further and shaped into a high-quality end product and is discharged from the crusher.

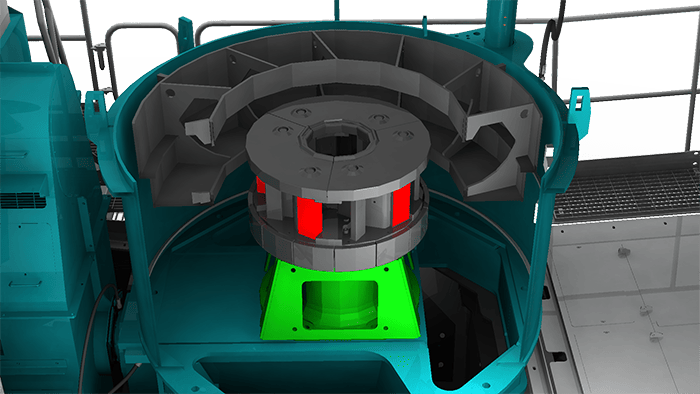

VSI crushers

Mobile Impact Crushers

Horizontal and vertical impact crushers from Powerscreen and Evoquip, the compact crushing and screening specialists.

Nothing makes a job run smoother than having the right equipment, parts, service and technical support in place, when you need it. Our goal is to help you put as much finished product on the ground with the least amount of grief possible.

Nothing makes a job run smoother than having the right equipment, parts, service and technical support in place, when you need it. Our goal is to help you put as much finished product on the ground with the least amount of grief possible.We’ve been the authorized dealer for Powerscreen since 1984 and Evoquip Compact Crushing and Screening Equipment since their start-up in 2017.

We carry the complete line of mobile crushing, screening, and conveying equipment, parts and employ factory-trained service personnel to get you up and running and keep you running as fast as possible.

If you’re thinking about renting, or you want to buy, or you’re just not sure, drop us a line. We’re here to help.

Trakpactor Mobile Impact Crushers

The Powerscreen® Trakpactor series of horizontal impact crushers offers producers a high reduction rate and excellent product shape for quarry and recycling applications.

With track mobility, the impactor can work in the most demanding environments and producers will appreciate the rapid setup time, fuel-efficient drive systems, and excellent throughput capacity.

Powerscreen Impactors are packed with high-performance features designd to increase uptime and provide fast set up.

- Hydraulic banks, battery access and control valves are at eye level to make setup and operation much easier.

- Large hoppers to reduce loader cycling times and provide a constant flow to the crusher.

- Vibrating grizzly feeders to remove fines before the crusher to imorove performance and optimize wear life.

- Easy access to service points

- Enhanced material flow features

- Direct drive via Desch gearbox for fuel efficiency

- Powerscreen Pulse – Remote monitoring package.

Trakpactor 260 / 260SR

| Output Potential | 250 tph* (275 US tph) |

| Transport Dimensions | Width: 8’3″ Length: 44’4″ Height: 10’6” |

| Working Dimensions | Width: 12’11” Length: 44’1″ Height: 11’3″ |

| Weight | Tier 3: 58,092lbs Tier 4: 56,769lbs |

| CSS Range | Min lower: .75″ Max lower: 2″ Min upper: 1.6″ Max upper: 4.7″ |

The Powerscreen® Trakpactor 260SR is a compact impact crusher which has been designed to offer excellent reduction and high consistency of product yield. With its compact design and ease of mobility, the Trakpactor 260SR is primarily suited to recycling, demolition, and mining applications. A post-screen system and recirculating conveyor allows oversize material to be passed back to the crusher for further sizing.

| Output Potential | Output potential up to 250 tph* (275 US tph) |

| Transport Dimensions | Width: 9’10” Length: 48’8″ Height: 10’6” |

| Working Dimensions | Width: 19’1″ Length: 51’10” Height: 12’8″ |

| Weight | Tier 3: 71,650lbs Tier 4F: 74,847lbs |

| CSS Range | Min lower: .75″ Max lower: 1.6″ Min upper: 2″ Max upper: 4.7″ |

Trakpactor 290 / 290SR

| Output Potential | 290 tph (320 US tph) |

| Transport Dimensions | Width: 8’4″ Length: 32’9″ Height: 10’5″ |

| Working Dimensions | Width: 17’1″ Length: 41’5″ Height: 12’2″ |

| Weight | 63,273lbs |

| CSS Range | Min lower: .75″ Max lower: 3″ Min upper: 2″ Max upper: 6″ |

The Powerscreen Trakpactor 290SR Impact Crusher performs in the most challenging of applications such as construction and demolition, asphalt, concrete, and natural rock. The compact design allows it to operate in small landing spaces and easily be transported from site to site. The integrated system on the 290SR ensures the required product specification is achieved with oversize material either being recirculated back to the crusher or stockpiled.

The Powerscreen Trakpactor 290SR Impact Crusher performs in the most challenging of applications such as construction and demolition, asphalt, concrete, and natural rock. The compact design allows it to operate in small landing spaces and easily be transported from site to site. The integrated system on the 290SR ensures the required product specification is achieved with oversize material either being recirculated back to the crusher or stockpiled.

| Output Potential | Output potential 290 tph (320 US tph) |

| Transport Dimensions | Width: 9’6″ Length: 48’5″ Height: 10’5″ |

| Working Dimensions | Width: 17’1″ with bypass conveyor Length: 48’5″ Height: 13’6″ |

| Weight | 75,398lbs |

| CSS Range | Min lower: .75″ Max lower: 3″ Min upper: 2″ Max upper: 6″ |

Trakpactor 320/ 320SR

| Output Potential | 320 tph (352 US tph) |

| Transport Dimensions | Width: 8’5″ Length: 48’6″ Height: 11’4″ |

| Working Dimensions | Width: 18’2″ with bypass conveyor Length: 47’1″ Height: 12’8″ |

| Weight | Tier 4F VGF: 80,601lbs Tier 4F Pre-screen: 84,128lbs |

| CSS Range | Min lower: .75″ Max lower: 2″ Min upper: 3″ Max upper: 6″ |

The Powerscreen Trakpactor 320SR is a mid-sized impactor redesigned with key enhancements to offer operators and contractors excellent reduction and high consistency of product shape. Powerscreen® Trakpactor 320SR features a screen and recirculating (SR) conveyor which returns oversized product to the crusher for further reduction. The plant features a quick-detach post-screen section which converts it to a standard Trakpactor 320 unit. Another key feature is the recirculating conveyor which raises for transport allowing more ground clearance under the machine when moving on site and while loading for transport.

| Output Potential | 320 tph (352 US tph) |

| Transport Dimensions | Width: 10’2″ Length: 57’8″ Height: 11’4″ |

| Working Dimensions | Width: 19’1″ with side conveyor Length: 56’6″ Height: 15’5″ |

| Weight | Tier 4F VGF: 102,647lbs Tier 4F Pre-screen: 112,436lbs |

| CSS Range | Min lower: .75″ Max lower: 2″ Min upper: 3″ Max upper: 6″ |

Trakpactor 550/ 550SR

| Output Potential | 500tph (550 US tph)* |

| Transport Dimensions | Width: 9’10″ Length: 57’5″ Height: 16’10” |

| Working Dimensions | Width: 22’10” with bypass conveyor Length: 58’6″ Height: 16’9″ |

| Weight | Tier 3 VGF: 120,924lbs Tier 4F Pre-screen: 126,656lbs |

| CSS Range | Min lower: .75″ Max lower: 8″ Min upper: 1.4″ Max upper: 8″ |

The Powerscreen® Trakpactor 550SR is a tracked impact crusher which is versatile, efficient and highly productive. It offers both excellent reduction and a high consistency of product yield in quarrying, recycling and demolition applications. The machine has been designed with excellent material flow and serviceability in mind. In addition, the machine can be configured for work safely and in record time as set-up is all carried out at ground level. The robust Terex impact chamber features c-shaped blowbars as standard for better impact and a time-saving hydraulic adjust option.

| Output Potential | 500tph (550 US tph)* |

| Transport Dimensions | Width: 11’4″ Length: 70’4″ Height: 12’6″ |

| Working Dimensions | Width: 22’11” with bypass conveyor deployed Length: 69’11” Height: 19’2″ |

| Weight | Tier 3 VGF: 147,269lbs Tier 4F Pre-screen: 158,733lbs |

| CSS Range | Min lower: .75″ Max lower: 8″ Min upper: 1.4″ Max upper: 8″ |

Powerscreen XV350 VSI

| Output Potential | 350tph (386 US tph)* |

| Transport Dimensions | Width: 9’10” Length: 50’8″ Height: 12’8″ with folding hopper extensions |

| Working Dimensions | Width: 12’8″ Length: 51’2″ Height: 15’1″ |

| Weight | 81,350lbs |

Evoquip Compact HSI crushers

![]()

Evoquip Cobra Impact Crushers provide class-leading productivity, unmatched versatility and excellent fuel efficiency for rock crushing. The quick setup times, simple, intuitive operation, and ease of transport make these machines ideal for the most demanding applications like Reinforced Concrete, Recycled Asphalt, C&D waste, and Natural Rock.

Features:

- Easy service access with ‘walk in’ ability at the rear to access engine dipstick/filters etc.

- Intuitive ‘Push button’ control system

- Output potential up to 290tph / 320 US tph

- Hydraulic adjust and hydraulic overload as standard

- Integrated pre-screen for fines removal

- Feeder speed auto-regulates depending on crusher load

- Replaceable 10mm (3/8”) wear liners on feeder floor

The largest of the crushers, the 290, is 32′ long and just over 8′ wide and can crush up to 390 tons per hour. Not only will they fit where most other crushers can’t, but you can also take it home and park it in your driveway for the night.

2018 Evoquip Cobra 230 For Sale Or Rent 914151

The Cobra 230R is a versatile and easy to use Small Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste and Natural Rock. The integrated Afterscreen system on the Cobra 230R ensures the required product specification is achieved with oversize material either being recirculated back to the Crusher or stockpiled.

| Specification | Value |

|---|---|

| Transport Length | 43′ 7″ |

| Transport Width | 8′ 3″ |

| Transport Height | 9′ 10″ |

| Diameter Rotor | 33″ x 34″ |

| Output Potential | 275 US tph |

Cobra 230 Crushing Asphalt

No matter what line of work you’re in, whether it is Construction & Demolition, Asphalt Recycling, Quarrying or Contract Crushing the Cobra 230 Portable Impact Crusher will enhance your profitability. The Cobra 230 Impact Crusher is a machine that provides class leading productivity, unmatched versatility and excellent fuel efficiency. The quick set up times, simple intuitive operation and ease of transport makes this machine an ideal solution for all applications.

| Transport Length | 30′ 7″ |

| Transport Width | 8′ |

| Transport Height | 9′ 10″ |

| Diameter Rotor | 33″ x 34″ |

| Output Potential | 275 US tph |

The Cobra 290R is a versatile and easy to use Track Mounted Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste and Natural Rock. The integrated Afterscreen system on the Cobra 290R ensures the required product specification is achieved with oversize material either being recirculated back to the Crusher or stockpiled.

The Cobra 290R is a versatile and easy to use Track Mounted Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste and Natural Rock. The integrated Afterscreen system on the Cobra 290R ensures the required product specification is achieved with oversize material either being recirculated back to the Crusher or stockpiled.

| Specification | Value |

|---|---|

| Transport Length | 48′ 5″ |

| Transport Width | 9′ 6″ |

| Transport Height | 10′ 4″ |

| Diameter Rotor | 40″ x 41.5″ |

| Output Potential | 320 US tph |

| Specification | Value |

|---|---|

| Transport Length | 43′ 7″ |

| Transport Width | 8′ 3″ |

| Transport Height | 9′ 10″ |

| Diameter Rotor | 33″ x 34″ |

| Output Potential | 275 US tph |

The Cobra 290 Tracked Impact Crusher is a machine that provides class leading productivity, unmatched versatility and excellent fuel efficiency. The quick set up times, simple intuitive operation and ease of transport makes this machine an ideal solution for all applications.

The Cobra 290 Tracked Impact Crusher is a machine that provides class leading productivity, unmatched versatility and excellent fuel efficiency. The quick set up times, simple intuitive operation and ease of transport makes this machine an ideal solution for all applications.

| Transport Length | 32′ 6″ |

| Transport Width | 8′ 4″ |

| Transport Height | 10′ 4″ |

| Diameter Rotor | 40″ x 41.5″ |

| Output Potential | 320 US tph |

Get the Answers You Need