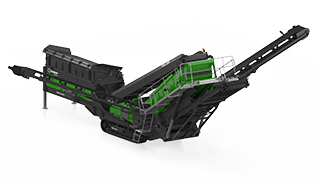

Inclined Screens

Add Versatility, Increased Production and Lower Operating Costs.

Inclined screens are highly efficient because they use a vibratory circular motion to lift the material into the air and gravity to move it along the screen’s surface. This process requires less energy than horizontal screens, which must generate enough power to lift the material into the air and move it across the screen.

Our mobile, inclined screen lineup consists of the Powerscreen Chieftain series and Evoquip Falcon Compact Inclined screens

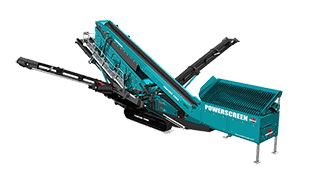

Powerscreen Chieftain Inclined Screens

Unleashing Versatility and Efficiency

The Powerscreen Chieftain range of mobile incline screens are designed for the processing of aggregates and sand.

The Powerscreen Chieftain range of mobile incline screens are designed for the processing of aggregates and sand.

From the legendary Chieftain 1400 to the monstrous Chieftain 2200, available in double-deck and triple-deck varieties, All Powerscreen Chieftain machines are designed to be easily transported, set up, set up, operated and maintained while giving excellent tonnages of in-spec material.

Chieftain 1700X

Chieftain 1700X 5’x 17′ 3-Deck Screen

The Powerscreen® Chieftain 1700 with 2 or 3 decks is a mid-sized mobile screen designed for high-volume producers requiring high throughput and mobility.

Increased Uptime

A drop-down tail conveyor, screen mesh access system, and transverse power unit arrangement simplify maintenance and servicing.

Features include:

- Radio-controlled tipping grid

- Heavy-duty single shaft screen box

- Adjustable stroke, angle, and speed.

Applications:

Sand & Gravel, Topsoil, Coal, and Iron Ore.

Output Potential: Up to 500 tph

Transport Dimensions

Width: 9’10″ (3m) Length: 54’3″ (16.53m) Height: 11’3″ (3.4m)

Working Dimensions

Width: 56’10″ (17.3m) Length: 56’6″ (17,22m) Height: 19’1″ (5.82)m

Weight: 59,304lbs / 26,900kgs

Screen:16’x5′ / 4.8m x 1.5m

Chieftain 2100X

Chieftain 2100X 5′ x 20′ 3-deck Screen

The Powerscreen Chieftain 2100X was designed for medium to large-scale operators who require large volumes of in-spec products.

Finely tuned screening for maximum production.

The screen box can be finely tuned to suit the application:

- Adjustable stroke, angle and speed,

- Transverse power unit arrangement,

- Drop-down fines conveyor to aid bottom deck mesh changes

Specifications

Output: 600 tph

Transport Dimensions

Width: 3m Length: 18.7m Height: 3.55m

Working Dimensions

Width: 18.25m Length: 19.17m Height: 6.72m

Weight: 2-Deck 76,500 lbs( 34,700kgs) 3-Deck 82452 lbs (37,400 kg)

Screen: 6.1m x 1.55m

Chieftain 2200

Chieftain 2200 5′ x 22′ 2-Deck Screen

The Powerscreen® Chieftain 2200 is designed for operators who require large volumes of high specification products with maximum versatility.

Revolutionary patent pending drive system

It has a revolutionary patent pending drive system which allows switching between 2 and 4 bearing with bolt-on parts.

The maximum variability of the Chieftain offers improved capabilities over its class rivals, especially in sticky scalping applications.

Output: Up to 650 tph

Transport Dimensions

Width: 9′ 10” (3m) Length: 64′ 11″ (19.8m) Height: 11′ 9” (3.6m)

Working Dimensions

Width: 59’11” (18.25m) Length: 65’7″ (20m) Height: 24′ 10″ (7.58m)

Weight: 79,366lbs / 36,000kg

Screen: 5’ x 22’ / 1.5m x 6.6m

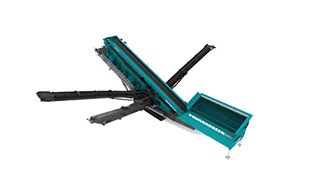

Falcon 1220

Falcon 1220 Inclined Mobile Screener

The Falcon 1220 5’x12′ 2-Deck mobile inclined screener combines scalping, screening and stockpiling into one self-contained unit. Its rugged design enables it to handle materials such as sand and gravel, crushed stone, coal, topsoil and demolition waste.

| Specification | Value |

|---|---|

| Transport Length | 49′ 3″ |

| Transport Width | 9′ 2″ |

| Transport Height | 60′ 3″ |

| Screen | 5′ x 12′ |

| Output Potential | 303 tph |

Falcon 1230

Falcon 1230 Inclined Screen

The Falcon 1230 5’x12′ 3-Deck Portable Inclined Screen, a solution for scalping, screening and stockpiling in a self-contained unit. A compact easily transportable machine that offers operators rapid set up and tear down times.

| Specification | Value |

|---|---|

| Transport Length | 55′ |

| Transport Width | 8′ 5″ |

| Transport Height | 11′ 3″ |

| Screen | 5′ x 12′ |

| Output Potential | 300 tph |