Slow-Speed, High-Torque, Industrial Shredders

A comprehensive guide to industrial shredders for waste management and recycling Get a quote

Slow-Speed, High-Torque, Industrial Shredders

A comprehensive guide to industrial shredders for waste management and recycling

Powerful Mobile Shredders for All Types of Waste and Waste Management

Slow-speed, high-torque industrial shredders are the backbone of any operation in waste management and recycling; understanding their importance is crucial for anyone involved in waste management, recycling, construction and demolition (C&D), agriculture, forestry, and land management industries.

These advanced machines are designed to handle a wide variety of waste materials, offering a practical solution for reducing environmental impact and maximizing efficiency.

Applications and Benefits

MSW and Organics Recycling and Disposal

Municipalities have found considerable benefits in using these shredders for waste management. They can handle a wide array of materials, from plastics to organic waste, making them a lucrative choice for waste processing facilities.

Construction and Demolition (C&D) Waste

In demolition and construction sites, these shredders can process a wide range of materials, including metals and plastics. This reduces the need for separate waste management systems, saving dollars and increasing efficiency.

Land Clearing and Site Clean-Up

Low-speed, high-torque shredders are ideal for land clearing, where they can handle large pieces of wood and organic waste. Their slow speed and high torque ensure that the material is shredded into manageable sizes, making further processing or recycling easier.

When used independently, shredders are highly effective in reducing the size of various waste materials and transforming bulky items into manageable pieces for easier disposal or further processing. Alternatively, they can act as the first stage in a comprehensive recycling process, breaking down waste into smaller sizes more suitable for subsequent sorting, separation, and material recovery. Whether functioning as standalone units or as part of a multi-step recycling chain, shredders are indispensable in optimizing waste management and promoting a more sustainable approach to resource utilization.

Mobile shredders provide mobility, productivity and versatility.

- Mobile shredders are self-contained, set up fast and easy to move.

- Shredders produce a higher quality finished product that is consistent in size and uniform shape.

- They run at a slower speed and use high torque, which means that even the most challenging material is reduced to the required size in one pass, resulting in substantial fuel savings.

- Their design, which combines low rotor speed with high torque, minimizes energy use while maintaining product quality.

- They are versatile and able to process a wide variety of materials in Recycling, Waste Processing/Management, Land Clearing and Environmental applications.

- The mobility of these shredders offers significant advantages like flexibility and cost-effectiveness. They can be used in multiple locations, from construction sites to landfills, eliminating the need to move materials for off-site shredding, and their compact size and onboard power make them an excellent choice for remote locations and job sites where space is limited. Producers can quickly load the machine on a low-bed trailer for long-distance transportation.

Immediate Benefits of Using Industrial Shredders

Industrial shredders offer immediate advantages that can be incredibly lucrative for businesses.

High-Value Commodities Recovered

Shredders play a crucial role in the recovery of valuable commodities. The list is extensive, from ferrous and non-ferrous metals to various types of plastics and even organic waste. By recovering these commodities, shredders contribute to the circular economy, reducing waste and the need for new raw materials.

Cutting Down on Landfill Costs and Associated Fees with Shredded Wood and Green Waste

Utilizing slow-speed, high-torque industrial shredders in land-clearing projects offers a cost-effective and eco-friendly solution for waste management. Shredding wood and green waste on-site transforms them into smaller, more manageable pieces. These shredded materials can be used directly on the site for various purposes such as mulch, compost, or natural erosion barriers. This eliminates the need to haul the waste to landfills, saving significant dollars in disposal fees and transportation costs. Moreover, it enhances the sustainability of land-clearing projects by promoting the recycling and reuse of organic materials.

Minimizing Expenses for Fuel, Labor, and Transporting Materials Through On-Site Use

When slow-speed, high-torque industrial shredders are used directly on-site, they offer an unparalleled advantage in cost savings. One of the most significant benefits is eliminating disposal and transportation fees. Since the shredded materials can often be recycled or reused on-site—as is the case with wood and green waste in land clearing projects—there’s no need to transport them to a landfill or recycling facility. This saves on fuel and eliminates the labour and logistical costs associated with waste transportation. By handling on-site waste management, you’re cutting out the middleman and making the entire process more efficient and cost-effective. This approach minimizes expenses and contributes to a more sustainable and environmentally responsible operation.

Foreman Equipment offers three proven and robust shredders from Komptech and EvoQuip.

- Komptech Terminator – Single-shaft

- Komptech Crambo – Dual-Shaft

- The Caiman 150 Compact Shredder

These machines are designed to handle a wide range of materials, from heavy contaminated construction debris to municipal solid waste.

Terminator

Low-Speed, Single Shaft Shredder

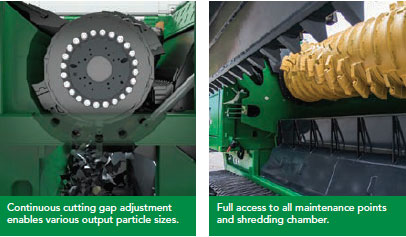

The Terminator is a low-speed, high-torque, single-shaft shredder designed to process nearly all types of difficult waste, including heavy contaminated C&D debris, bulky waste, white goods, mattresses, tires and municipal solid waste (MSW).

- Remote-controlled hopper with 11-foot feed opening.

- The hydraulic drum drive can reverse at any time for self-cleaning.

Terminator 3400S

Diesel Engine / Horsepower: Cat C9 Tier 4F 330 HP

Travel Dimensions: 25’8″ x 9’4″ x 11’10” (7.8 x 2.9 x 3.6 m)

Maximum Weight: 57,000 lbs

Maximum Throughput: up to 55 tons/hr

Terminator 6000S

Diesel Engine / Horsepower: Cat C18 Tier 4F 600 HP

Travel Dimensions: 25’8″ x 9’4″ x 11’10” (7.8 x 2.9 x 3.6 m)

Maximum Weight: 60,000 lbs

Maximum Throughput: up to 110 tons/hr

Crambo

Low-speed, Double Shaft Shredder

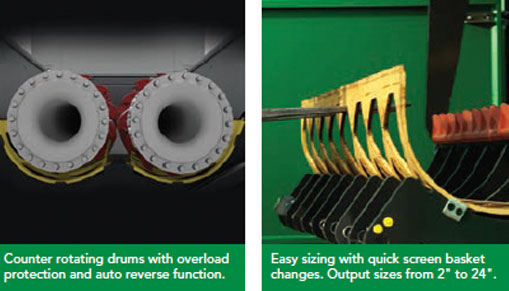

The Crambo is a dual-shaft shredder engineered to deliver high-throughput shredding of the toughest wood and organic waste materials while mixing and blending to provide a homogeneous output.

- Designed to withstand heavy contamination.

- Low maintenance, fuel consumption and operating costs.

Crambo 3400

Diesel Engine / Horsepower: CAT® C9 Tier 4F / 330 HP

Travel Dimensions: 25′ x 9’4″ x 11’2″ (7.5 x 2.9 x 3.4 m)

Maximum Weight: 54,000 lbs

Maximum Throughput: up to 50 tons/hr

Crambo 6000

Diesel Engine / Horsepower: CAT® C18 Tier 4F / 600 HP

Travel Dimensions: 25′ x 9’4″ x 11’2″ (7.5 x 2.9 x 3.4 m)

Maximum Weight: 58,000 lbs

Maximum Throughput: up to 110 tons/hr

Caiman 150

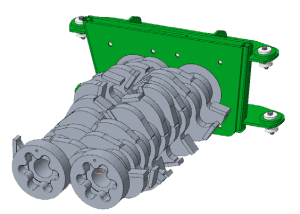

Compact Low-speed, Double Shaft Shredder

The EvoQuip Caiman 150 compact shredder is the first to be added to the expanding crushing and screening portfolio. The Caiman 150 is a Terex designed and built machine and is designed to excel in the most demanding recycling applications.

- Compact design

- Low maintenance, fuel consumption and operating costs.

Diesel Engine / Horsepower: T3: Cat C4.4 129kW @ 1850rpm Stage V/T4F: Cat C4.4 140kW @ 1850rpm Efficient hydrostatic drive arrangement.

Travel Length: 27′ 8″ / 8.4m

Travel Width: 8′ 2″ / 2.5m

Weight: 36,376lbs / 16,500kg

Contact us today to learn more about how our industrial shredders can drive profits and reduce your operational costs.