See the M413 in action!

There are many different ways to sort rock after blasting. Some methods are much more labour-intensive, but all will eventually get the job done. The least efficient way to screen all of that blast rock is to dump loader buckets full of material onto a stand-alone stationary grizzly. Not only is it hard work, but it takes a very long time to complete. Traditional rip rap plants rely on grizzly bars and step-deck grizzly feeders to separate and sort rock by size. The third method is to use a heavy-duty rock trommel screen.

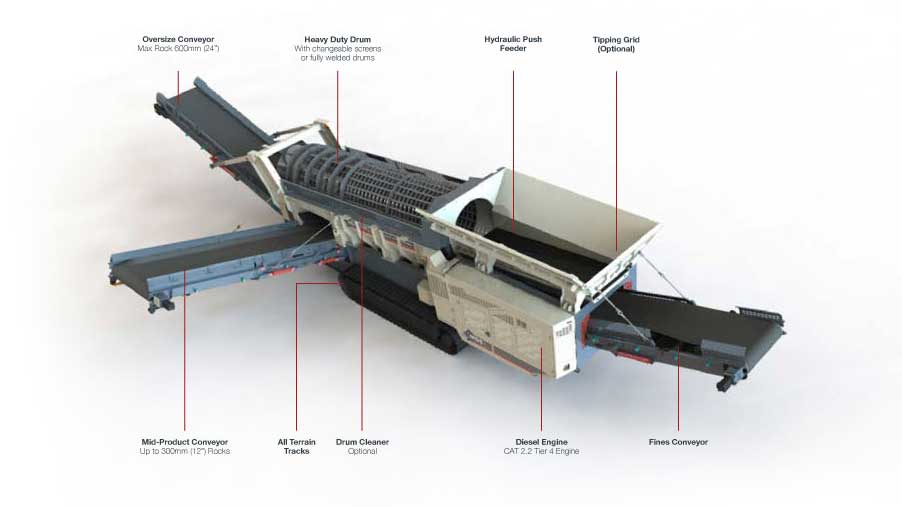

Trommel’s use a large rotating drum with different size screen openings to sort material. The drums contain different sections fitted with various size openings to sort multiple rock sizes. Trommels’ ability to clean wet, stick material or clay-bound rock sets them apart from other riprap plants.

Specs & Dimensions

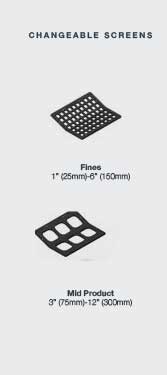

Screen Media Options

Machine Specifications

Weight

65,036 lbs / 29.5 Tonnes

Feeder

Hydraulic Push Feeder / Hydraulic Push Feeder

Drum

Diameter: 4′ 1″ (1.25m) Length: 13′ 1″ (4m)

Max Rock Size: 24″ (600mm)

Approx. Tons/Hour: 300

Transport Dimension

Length: 43’ 11” | Width: 8’29” | Height 8′ 2”

Working Dimensions

Length: 55’ 3” (16,851 mm) | Width: 24’ 10”