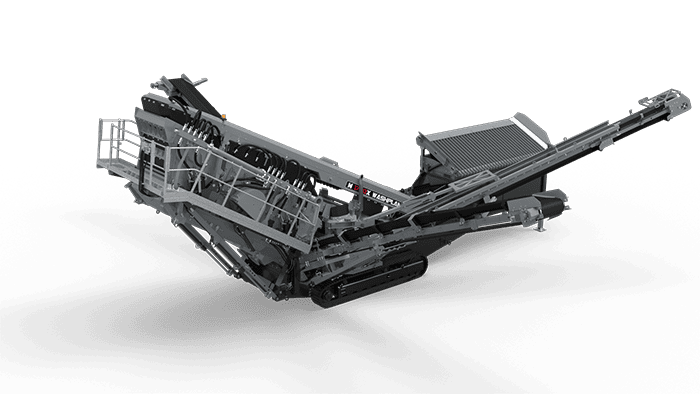

The Ultimate Mobile Washing Solution

Foreman Equipment is proud to present Terex Washing Systems’ M1700 and M2100 mobile wash screens, the most flexible and efficient washing solutions in the market. These innovative systems are designed to meet the demands of the aggregate industry, providing unmatched performance and adaptability.

Switch Wet to Dry Screening Easily

Terex Washing Systems (TWS) Mobile Rinsers let you switch from wet to dry as needed. The TWS M-Series range offers no-compromise mobile screening with the ability to operate either wet or dry with quick and easy change from dry to washing duty.

Pair With Advanced Washing and Sand Processing Gear for Technical Specifications.

If you need a loose crusher run as well as maximum sub-base production one day and are working with clay-contaminated seams with a need for high-quality concrete aggregates the next, you have the right machine. If you need in-spec washed sand from an all-in feed, the M-Series can be partnered with TWS’s FM120C cyclone-based sand washing unit or T150 bucket wheel dewaterer for a high performance and extremely versatile sand washing system with minimal site preparation required.

Highly Versatile In A Range of Applications From Sand & Gravel to C&D Processing

TWS M-Series mobile rinsers have repeatedly proven their merit in applications ranging from construction and demolition waste to iron ore mining, concrete and building materials production, industrial sands processing, contract crushing lines and civil engineering projects. In each case, whether working directly for a site owner-operator or as part of a rental fleet, the extreme ease of deployment, setup, operation and maintenance has delivered sector-defining return on investment and consistently high quality product on the ground.

Choose between 4 core unit sizes with screens up to 5’x20′, 2 and 3 deck options and a choice of Tier 3 / Tier 4 and dual power capability. With some versions offering a wheel or track-mounted configuration choice, operators can even select how to bring it to the material.

Unparalleled Versatility and Efficiency

- Rapid Setup: Get up and running in under 15 minutes, ensuring minimal downtime.

- High Capacity Produce up to 5 different products, catering to diverse operational needs.

- Flexible Applications: Convert to a dry screening application within hours with the available adaption kits.

Available Options

- Engine Options: Select from tier 3, tier 4, and dual-power electric drive options for optimal performance.

- Track or Wheel Mounted: Choose the mounting option that best suits your project requirements.

Eco-Friendly Operation

- Energy Efficiency: Optional dual-power electric drives and optimized engine performance reduce greenhouse gas emissions.

- Advanced washing techniques and recycling capabilities minimize water consumption.

- Reduced Waste: Precise screening processes and durable construction result in less waste and environmental impact.

- Noise Reduction: Quiet operation minimizes disruption to surrounding communities and wildlife.

Advantages of Terex M-Range Wet Screens

The M-Range screens can operate independently or integrate seamlessly with existing washing systems, making them ideal for both short and medium-term projects. With their quick setup time, high capacity, and eco-friendly features, the M1700 and M2100 are designed to enhance your aggregate operations efficiently and sustainably.

Key Shared Features

- Mounting Options: Available in both track-mounted and wheeled configurations

- Integrated Feed Hopper: Ensures continuous material flow

- On-Board Discharge Conveyors: Facilitates efficient material handling

- Flexible Screening: Adaption kits for converting to dry screening applications

![]() Downloads

Downloads

Technical Specifications of Terex Washing Systems’ M-Range Screens

M1700 Mobile Wash Screen

Screen Size: 5’ x 16’ (1.52m x 4.88m) 3-Deck

Feed Hopper Capacity: 9.2yd³ (7m³ )

Power:

- Engine Options: Tier 3 / Tier 4 diesel engines,

- Dual Power (electric drive option) Electric Drive: 45 kW (60 HP)

Performance:

- Production Rate: Up to 300 tph (tonnes per hour)

- Product Output: Up to 5 products

M2100 Mobile Wash Screen

Screen Size: 5′ x 20′ (1.52m x 6.1m) 3-Deck

MaterialFeed Hopper Capacity: 10m³ (13 yd³)

Power:

- Engine Options: Tier 3 / Tier 4 diesel engines, Dual Power (electric drive option)

- Dual Power (electric drive option) Electric Drive: 55 kW (75 HP)

Performance:

- Production Rate: Up to 400 tph (tonnes per hour)

- Product Output: Up to 5 products

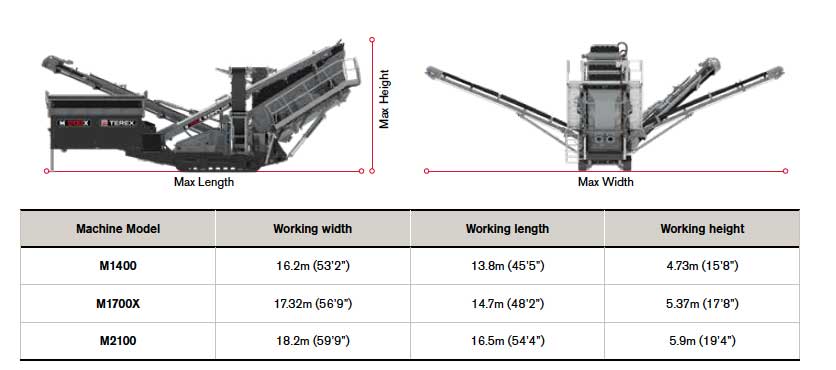

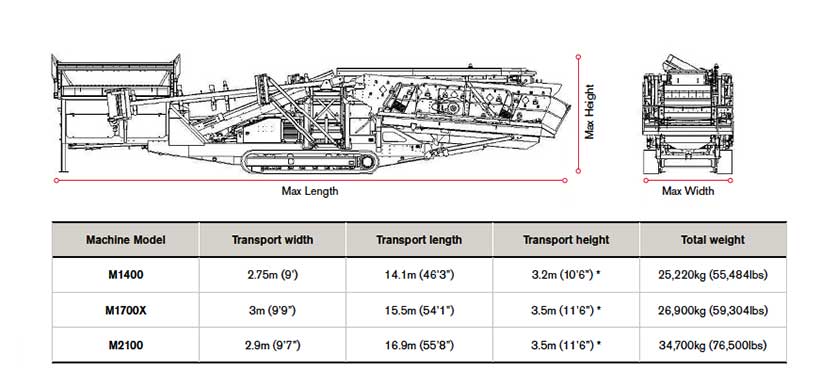

M-Series Wet Screen Weights & Dimensions

Features of Terex Washing Systems M-Range Wet Screens

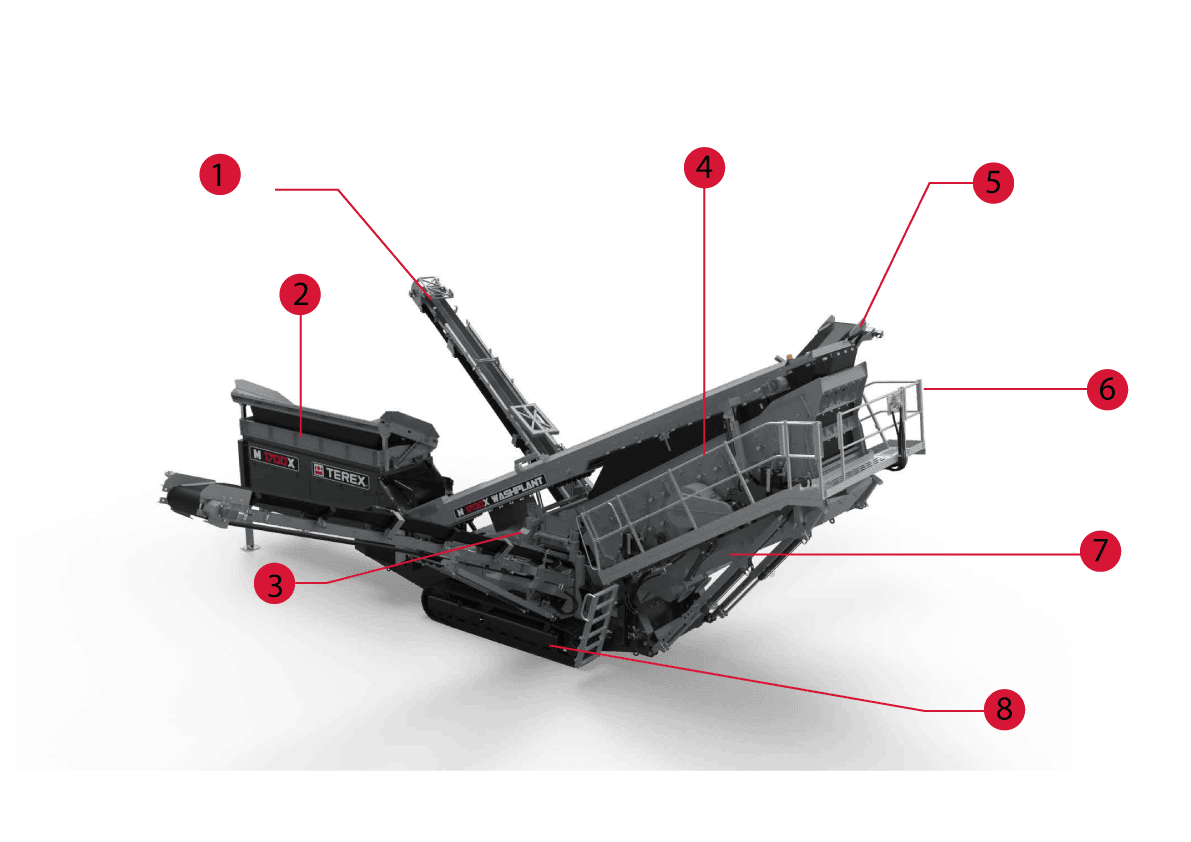

1. Hydraulic folding product conveyors

- Independent speed control

- Optional hydraulic extended auxiliary conveyor complete with transfer conveyor

2. High-capacity belt feeder

up to 600 tph / 661 US tph (depending on media sizes & material type)

- Hydraulic tipping reject grid (4”) as standard with radio remote control tipping grid

- Optional – Low profile double deck vibrating gridangle adjustable and fully riveted construction

- Maximum feed size 150mm (6’’)

3 Power unit featuring a transverse engine arrangement to aid access & serviceability

- Engine protection shutdown system

- High performance hydraulic system—cast iron pumps & motors complete with oil cooler

- Optional hybrid dual power and fuel save options available

4. Heavy duty fully riveted incline screen with adjustable stroke, angle & speed

- Side tensioned top and middle deck screen mesh

- Hydraulic assisted end tensioned bottom deck mesh

- Screen mesh access system for quicker mesh changes

- Independently controlled spraybars for class leading rinsing

- All decks have brass nozzles and are designed to give full spray coverage

5 Integrated high volume washbox

- Multi nozzle water injection with flow control

6 Galvanised all-round screen access

- Easy folding for rapid set-up

7. Fines collection catch box, single or double grade with adjustable division plates (rubber lined).

- Hydraulically raised & lowered for ease of maintenance

8 Maximum mobility with heavy duty, low-ground pressure tracks

- Removable heavy-duty pendant remote control system

Contact Us Today!

Join the forefront of the aggregate industry with Foreman Equipment and Terex Washing Systems. Discover how the M1700 and M2100 can transform your operations and deliver unmatched performance and flexibility.