Scalping Screens Built to Tackle the Toughest Material

High-capacity, heavy-duty screening equipment engineered to handle rock, rubble, and overburden with ease—keeping your operation moving and your feed clean. Talk to an ExpertEngineered for Efficiency, Designed for Durability

Scalping screens are crucial in industries like aggregates, recycling, land clearing, and disaster recovery. They enhance operational efficiency, environmental sustainability, and safety. Understanding their functions, benefits, and maintenance can help businesses improve their operations, support sustainability, and increase efficiency.

Types of Scalping Screens

Scalping screens are available in various designs and configurations, including vibrating screens, grizzly screens, and trommel screens, scalping screens offer versatility in different applications and operating conditions.

Different screen openings, deck configurations, and drive systems can be customized to suit specific processing requirements and material characteristics

Vibrating Grizzly Feeder

Vibrating grizzly feeders are essential for efficient operation in industries like mining, aggregates, and recycling. These feeders use a vibrating mechanism to remove undersized rock and fines that are too small to be crushed, ensuring that only appropriately sized material enters the processing system. By pre-screening and isolating smaller debris, vibrating grizzly feeders protect downstream equipment from potential blocking and bridging that can cause damage and reduce operational downtime. Their robust design and reliable performance make them indispensable for maintaining a continuous, smooth workflow, enhancing overall productivity, and improving the longevity of other machinery in the processing line.

Grizzly Bars

Grizzly bars are essential components in the mining, aggregates, and recycling industries, used for primary screening and sorting of materials. These sturdy, heavy-duty bars are designed to withstand harsh conditions and efficiently separate large rocks and debris from finer materials, preventing damage to downstream processing equipment. By effectively removing oversized materials, grizzly bars enhance the efficiency of the screening process, reduce wear and tear on machinery, and contribute to safer, more streamlined operations.

Versatile and Able to Screen a Wide Range of Material in Most Applications.

Mobile scalping screens are versatile and able to screen a variety of materials in many applications.

- Mounted on tracked chassis’ and equipped with onboard engines, mobile equipment:

Has a smaller footprint enabling them to access job sites with limited space. - Self-contained and don’t require external power so they can work in remote locations.

- Track-mounted and self-powered so they can walk off of a low-boy and crawl onto the site.

- Has production capabilities equal to or greater than their wheel portable counterparts.

Our lineup of mobile scalping screens consists of the Warrior line from Powerscreen and Evoquip Colt and Harrier compact screens. Two of the most trusted manufacturers of mobile crushing and screening equipment in the world.

Typical scalping screen applications include:

Blast Rock / Quarrying, Recycling Concrete & Asp, Sand & Gravel, Compost, Topsoil, Coal, Construction and Demolition Waste, Iron Ore

Screening Links

Downloads

Downloads

Resources

Learn More About

Types of Screens

Inclined / Finishing Screens

Horizontal Screens

Trommel Screens for Aggregates

Scalping Screens For Sale or Rent

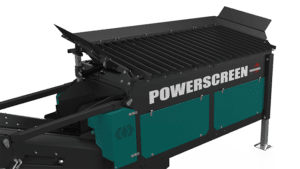

Powerscreen Warrior Scalping Screens

The Powerscreen® Warrior range are high capacity, heavy duty, versatile machines capable of screening and separating a wide variety of material in the most difficult and demanding of applications.

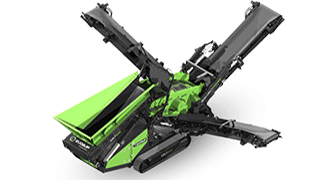

Warrior 800

Warrior 800 4′ x 9′ 2-Deck Scalping Screen

Designed for the small operator who requires versatility and ease of transport.

The Warrior 800 4′ x 9′ 2-Deck screen is a heavy-duty 2-deck screen capable of stockpiling, 3-way splitting or scalping before and after the crusher.

User benefits include:

- Rapid set-up time

- Easy operation

- Hydraulic folding tail and side conveyors,

- Rigid feed hopper sides

- Two-speed tracks.

| Output Potential | 280 tph (308 US tph) / 280 tph (308 US tph) |

| Transport Dimensions | Width: 8’2″ Length: 30’3″ Height: 10’1″ / Width: 2.5m Length: 9.22m Height: 3.09m |

| Working Dimensions | Width: 36’5″ Length: 46’3″ Height: 12’10” / Width: 11.11m Length: 14.09m Height: 3.92m |

| Weight | 36,817lbs / 16,700kgs |

| Screen | 9’1″ x 4″ / 2.77m x 1.22m |

Warrior 1200

Warrior 1200 4′ x 12′ 2-Deck Screen

The Powerscreen Warrior 1200 is the most compact 12ft scalping screen in today’s market. Despite this footprint, with a highly aggressive screen at its heart, the Warrior 1200 is not overshadowed by its competition.

Screen Media

Its highly aggressive screen can accept

- Bofor Bars

- Finger screens

- Woven mesh

- Punch plates

- Other application specific media types.

User benefits

include a rapid set-up time and ease of operation aided by hydraulically folding conveyors, two speed tracks and a swift two way split conversion.

| Output Potential | 300 tph (330 US tph) / 300 tph (330 US tph) |

| Transport Dimensions | Width: 7’5″ Length: 36′ Height: 8’3″ / Width: 2.25m Length: 10.96m Height: 2.51m |

| Working Dimensions | Width: 34’1″ Length: 38’2″ Height: 12’4″ / Width: 10.38m Length: 11.63m Height: 3.76m |

| Weight | 37,038lbs / 16,800kgs |

| Screen | 12′ x 4′ / 3.60m x 1.17m |

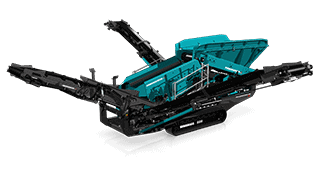

Warrior 1400X

Warrior 1400X 4.5′ x 12′ 2-Deck Screen

The Powerscreen® Warrior 1400X is a flexible screening machine, aimed at operators who require a high performing, heavy duty, versatile machine that remains easy to transport. It offers improved performance, lower operating costs, and easier serviceability while building on the reliable foundation of our class-leading Warrior 1400 scalper. A variety of media solutions mean that the Warrior 1400X is extremely efficient in scalping, screening and recycling applications and it can process mixed demolition waste including greenwaste, soil, concrete, wood and asphalt.

| Output Potential | 500 tph (551 US tph) / 500 tph (551 US tph) |

| Transport Dimensions | Width: 9′ Length: 46’6″ Height: 10’6″ / Width: 2.75m Length: 14.17m Height: 3.2m |

| Working Dimensions | Width: 41’3″ Length: 46’7″ Height: 15′ / Width: 12.58m Length: 14.23m Height: 4.57m |

| Weight | 60,848lbs / 27,600kg |

| Screen | 11’10” x 4’6″ / 3.6m x 1.37m |

Warrior 1800

Warrior 1800 5′ x 16′ Scalping Screen

Designed for medium to large operators, where high capacity and throughput are paramount, the Powerscreen® Warrior 1800 is a tough, heavy duty machine built for screening, 2 or 3 way splitting and stockpiling in quarrying, recycling, construction and demolition aggregates and top soil applications. With low ground pressure crawler tracks the Warrior 1800 is highly mobile. The versatile screen accepts a wide range of media options including bofor bars, finger screens, woven mesh and punch plates.

| Output Potential | 600 tph (661 US tph) / 600 tph (661 US tph) |

| Transport Dimensions | Width: 9’8″ Length: 50’6″ Height: 11’2″ / Width: 2.96m Length: 15.38m Height: 3.39m |

| Working Dimensions | Width: 41’4″ Length: 46’10” Height: 14’11” / Width: 12.6m Length: 14.26m Height: 4.55m |

| Weight | 63,934lbs / 29,000kg |

| Screen | 16’x5′ / 4.8m x 1.5m |

Warrior 2100

Warrior 1200 5′ x 16′ Screen

The Warrior 2100 is engineered to include Triple Shaft technology which is unique to Powerscreen heavy duty mobile screens. The triple shaft design ensures that the 16′ x 5′ screen box is highly efficient while maintaining exceptional throughput productivity. The extreme screening acceleration offers the Warrior 2100 improved capabilities over its class rivals, especially in sticky scalping applications. Whilst the Warrior 2100 sits within the same transport envelope as other machines in the 16′ x 5′ class, it has been proven to considerably outperform any conventional single shaft 16′ x 5′ screen.

| Output Potential | 700tph (772 US tph)* / 700tph (772 US tph)* |

| Transport Dimensions | Width: 9’10” Length: 52’5″ Height: 11’3″ / Width: 3m Length: 15.99m Height: 3.43m |

| Working Dimensions | Width: 44’7″ Length: 53’4″ Height: 15’4″ / Width: 13.6m Length: 16.26m Height: 4.68m |

| Weight | 81,351lbs / 36,900kg |

| Screen | 16′ x 5’1″ / 4.88m x 1.56m |

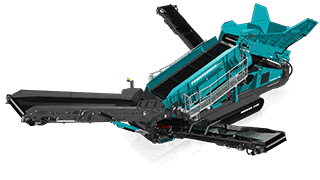

Warrior 2400

Warrior 2400 6′ 4″ x 20′ Scalping Screen

Specially designed for large scale operators in the quarrying and mining sectors, the Powerscreen® Warrior 2400 is capable of handling larger feed sizes and throughputs. It features a heavy duty incline screen with a high amplitude triple shaft drive mechanism, lending it to screening, scalping, 2 or 3 way splitting and stockpiling materials like aggregates, topsoil, coal, construction, demolition waste and iron ore. User benefits include a slide out tail conveyor facility to aid media access and a load sensing collection conveyor circuit to avoid blockages.

| Output Potential | 800 tph (881 US tph) |

| Transport Dimensions | Width: 3m Length: 17.3m Height: 3.6m |

| Working Dimensions | Width: 15.3m Length: 18.5m Height: 5.22m |

| Weight | 46,200kg |

| Screen | 6′ 4″ x 20′ |

Warrior 2400

Warrior 2400 6′ 4″ x 20′ Scalping Screen

Specially designed for large scale operators in the quarrying and mining sectors, the Powerscreen® Warrior 2400 is capable of handling larger feed sizes and throughputs. It features a heavy duty incline screen with a high amplitude triple shaft drive mechanism, lending it to screening, scalping, 2 or 3 way splitting and stockpiling materials like aggregates, topsoil, coal, construction, demolition waste and iron ore. User benefits include a slide out tail conveyor facility to aid media access and a load sensing collection conveyor circuit to avoid blockages.

| Output Potential | 800 tph (881 US tph) |

| Transport Dimensions | Width: 3m Length: 17.3m Height: 3.6m |

| Working Dimensions | Width: 15.3m Length: 18.5m Height: 5.22m |

| Weight | 46,200kg |

| Screen | 6′ 4″ x 20′ |

Evoquip Compact Screens

Colt Compact Scalping Screens

The Colt Range Screening Machines have a compact footprint while achieving versatility and mobility. Screens can operate in heavy-duty scalping and precision screening applications and will manage the most difficult materials.

Colt 600

Colt 600 4′ x 8′ 2-Deck Screen

The Colt 600 is a compact and aggressive forward-facing screen that can work in aggregates, sand and gravel, topsoil, construction demolition and recycling applications where site space is at a premium.

- Fits inside a container for transport

- Strong enough to withstand the most demanding applications.

| Specification | Value |

|---|---|

| Transport Length | 36′ / 10.98m |

| Transport Width | 7′ 5″ / 2.25m |

| Transport Height | 8′ 4″ / 2.55m |

| Double Deck Screen | 8′ x 4′ / 2.34m x 1.17m |

| Output Potential | 308 US tph / 280tph |

Colt 800

Colt 800 4′ x 9′ 2-Deck Screen

The Colt 800 Mobile Screening Machine is a compact and aggressive forward facing incline screen. This versatile plant can work in aggregates, sand and gravel, top soil, construction demolition and recycling applications where site space is at a premium. The highly aggressive screenbox can accept a range of media including bofor bars, finger screens, woven mesh and punch plates. Its compact size, quick set-up times, ease of transport and ease of operation makes the Colt 800 the ideal solution for all small to medium sized operators.

| Specification | |

|---|---|

| Transport Length | 30′ 3″ / 9.22m |

| Transport Width | 8′ 2″ / 2.5m |

| Transport Height | 10′ 1″ / 3.09m |

| Double Deck Screen | 9′ x 4′ / 2.77m x 1.22m |

| Output Potential | 308 US tph / 280tph |

Colt 1000

Colt 1000 4′ x 13′ 6″ 2-Deck Screen

The highly adaptable Colt 1000 Scalping screen is able to operate in both heavy duty scalping and precision screening applications and will manage the most difficult of materials. The Colt 1000 achieves a compact footprint maintaining the ethos of the EvoQuip range while achieving versatility and mobility. Flexibility is enhanced with configurable conveyor options and two way split conversion. Featuring an aggressive double deck screen, variable screening angle with numerous screen media options, broad fines conveyor, quick set up time and tall discharge heights ensures the Colt 1000 distinguishes itself amongst its competition.

| Specification | Value |

|---|---|

| Transport Length | 35′ 11″ / 11m |

| Transport Width | 8′ 2″ / 2.5m |

| Transport Height | 10′ 4″ / 3.1m |

| Double Deck Screen | 13’6” x 4′ / 4.1m x 1.22m |

| Output Potential | 396 US tph / 360tph |

Colt 1600

Colt 1600 5′ x 16′ 2-Deck Screen

The high capacity, versatile heavy duty Colt 1600 Screen is designed to work in primary and secondary screening applications. With the single, triple shaft and Spaleck screen box options the applications are endless. The Colt 1600 is available with dual power technology giving flexibility to be powered by an external power supply or the standard on-board engine.

| Transport Length | 49′ 1″ / 14.95m |

| Transport Width | 9′ 11″ / 3.0m |

| Transport Height | 11′ 2″ / 3.36m |

| Double Deck Screen | 16′ x 5′ / 4.8m x 1.53m |

| Output Potential | 600 US tph / 600tph |

Harrier Compact Scalping Screens

The Harrier range of mobile screens is versatile, robust and designed for multiple industries tackling everything from the most challenging scalping applications to fine screening.

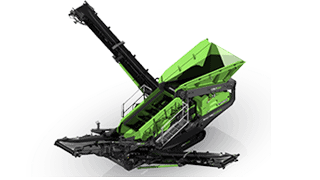

Harrier 220

Harrier 220 3′ 6″ x 6′ 9″ Scalping Screen

The Harrier 220 Compact Scalping Screen is a small yet robust machine designed for recycling, composting, topsoil, landscaping, and contract building industries. Its compact size, quick set-up times, ease of transport and ease of operation makes the Harrier 220 the ideal solution for smaller scale operations.

| Transport Length | 14′ 4″ / 4.36m |

| Transport Width | 5′ 11″ / 1.8m |

| Transport Height | 7′ 4″ / 2.23m |

| Double Deck Screen | 6′ 9″ x 3′ 6″ / 2.1m x 1.1m |

| Output Potential | 90 US tph / 80tph |

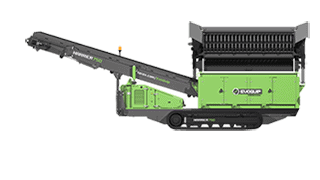

Harrier 750

Harrier 750 8′ 7″ x 14′ 8″ Screen

The Harrier 750 is a high capacity Mobile Screening Machine. With its robust construction the Harrier 750 can withstand the toughest scalping applications while still being versatile enough to perform at a high level in fine screening applications. It really is the perfect multipurpose machine for your site.

| Transport Length | 31′ / 9.43m |

| Transport Width | 9′ 3″ / 2.82m |

| Transport Height | 10′ 6″ / 3.2m |

| Double Deck Screen | 14′ 8″ x 8′ 7″ / 4.5m x 2.6m |

| Output Potential | 660 US tph / 600tph |

Talk to a Screening Expert.

Foreman Equipment’s scalping screens are indispensable tools across industries, designed to enhance efficiency and product quality through customization and versatility.

Whether you need more information or want a quote, our product support specialists are standing by to help you, any way we can.

Scalping Screens

* Indicates a Required Field