Screening Equipment for Rock, Stone, Sand, Gravel, Concrete and Asphalt.

Choosing the correct screener will increase efficiency, improve production and lower opertating costs Contact UsWhat is aggregate screening?

The screening process is arguably the most important process in aggregate production.

Screens are used throughout the aggregate, mining and recycling industries to classify and sort rock, stone, sand, construction rubble and other materials by size.

Crushers break rock and produce the gradation. But it’s the screens function to separate, size and sort the crushed material so it can be used in construction materials like road base, concrete and asphalt products.

The crusher produces the gradation, but the screen produces the specification. Until the crushed material is successfully screened, no money is made.

Are you looking for a fast, reliable way to screen rock, stone, sand, gravel and crushed concrete?

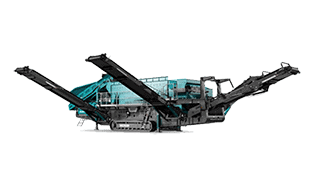

Warrior 1200 4′ x 12′ 2-Deck Screen

Look no further – our mobile track mounted screening equipment is the perfect solution.

With nearly forty years of crushing and screening experience, we can confidently say that it’s the most efficient and effective option available.

![]() Downloads

Downloads

Types of Screening Machines

While all screens are developed to sort and classify material by size, some are application-specific and designed to perform a specific range of duties like scalping, washing, and dewatering. The type of screen required depends on the application and material required.

Finishing Screens

Inclined Screens

Brand: Powerscreen Chieftain, Evoquip Falcon

Application: Sand & Gravel

Characteristics:

- Rapid Fines Removal

- Lower Operating Costs

Application Specific Screens

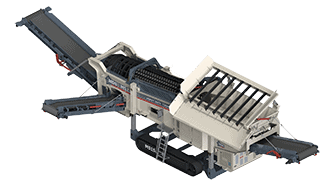

Scalping Screens

Brands: Powerscreen Warrior, Evoquip Colt

Applications: Blasted Rock / Quarrying, Recycling, Aggregates, Compost, Topsoil, Coal, Construction and Demolition Waste, and Iron Ore.

Characteristics:

- A wide range of screen media available.

- Able to screens a wide range of materials.

Wash Screens

Washing screens, also known as wet screens, are used to remove unwanted materials like silt, rock dust, and organic material from rock, stone, and sand to produce material that meets construction specifications.

Dewatering Screens

Dewatering screens have a wide range of uses, including removing water and slime and scrubbing washed sand, rock and stone. They produce a drip-free product that is immediately usable or salable.

Mobile track-mounted screens add mobility, versatility, and adaptability.

Mobile track mounted screeners are the most efficient method of screening large quantities of material.

• Self-Contained – No outside power required.

• Track-Mounted – Able to move over difficult terrain.

• Smaller Footprint – Access sites with limited or confined space.

• Rapid Mobility- Sets up in minutes, not hours.

• Site set up & training included.

Are you screaming the screening blues?

Our team is ready to help you accomplish more by delivering industry and product expertise combined with world-class parts and service support. How can we help you?

Talk with one of our Experts

Learn more about our brands.

Powerscreen Inclined and Scalping Screens:

- Warrior heavy-duty scalping screens – Recycling, Aggregates, Compost, Topsoil, Coal, C&D Waste

- Chieftain mobile inclined screens – Aggregates, sand

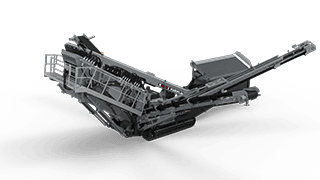

Evoquip Compact Screens are built to excel in both heavy-duty scalping and precision screening applications in aggregates, sand & gravel, construction and demolition.

- Evoquip Colt Compact Screens

- Evoquip Harrier