Washing Screens

From our unique track-mounted M-Series, which can operate on a wet or dry basis, to our comprehensive range of static and modular units for sizing and dewatering, TWS offers a substantial selection of screening machines covering numerous industries and applications.

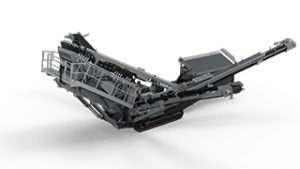

M Range Mobile Washing Screens

Terex M1700 Wash Screen

Capable of producing up to 5 products, they also offer adaption kits to convert to a dry screening application within hours, resulting in the M-series being the most flexible unit on the market.

Key Features

- Track-mounted or wheeled mobile washing screens with integrated feed hopper and onboard discharge conveyors

- Quick set-up time typically under 15 minutes

- Engine options to suit tier 3 & tier 4 as well as dual-power electric drive options

- Hydraulic-adjusted screen angle for optimum screening performance.

Aggrescalp

Key Features

- Semi-mobile

- Electric powered (40Kw)

- Integrated hydraulic pack for set up

- Pre wired & pre plumbed

- Quick set up

- Integrated discharge conveyors

- 2-way & 3-way split

The Terex AggreScalp™ is a versatile, high-performance heavy-duty electric screening machine that can operate as a 2-way or 3-way split screener. The highly aggressive screen can accept media, including bofor bars, finger screens, woven mesh and 3D punch plates, allowing it to be used across various applications.

Static Screen Range

The Terex® Screenbox Range is designed for maximum production efficiency in applications including sand and gravel, coal, crushed stone, slag, recycled materials, concrete, iron ore and silica glass.

Available in sizes ranging from 2.4m x 1.2m (8’ x 4’) up to 6m x 1.8m (20’ x 6’) all Screenboxes come with the choice of 2 or 3 Decks and a range of media options.

Key Features

- Produces up to 4 grades of washed aggregate and 1 or 2 grades of sand

- High efficiency – low maintenance direct electric drive

- Choice of side tensioned wire mesh or modular polyurethane decks to suit your application

- Isolated spraybars with individual flow valves provides complete water control

![]() Downloads

Downloads