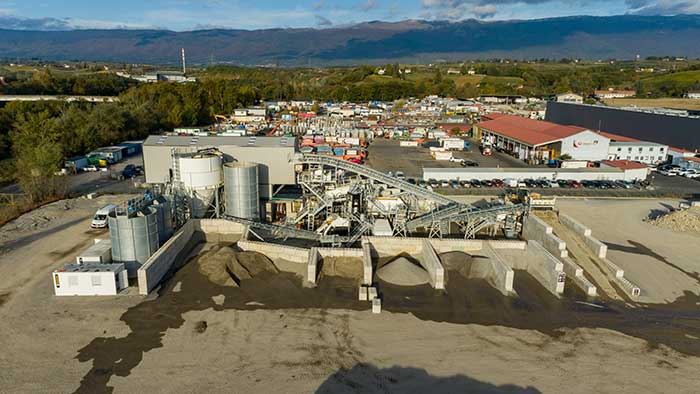

Sand Washing and Waste Recycling: Wet Processing Solutions

Foreman Equipment, in partnership with Terex Washing Systems, brings unparalleled washing solutions to British Columbia.From the heart of quarries to the core of recycling plants, Terex Washing Systems stands as a testament to innovative engineering and sustainable practices.

Power Your Project: Advanced Washing Solutions for Every Need

Wet processing technology has revolutionized the way materials are handled, processed, and recovered, offering significant advantages over traditional dry processing methods. Our solutions are designed to provide superior washing, classification, and dewatering capabilities. Our clients achieve the highest standards of product purity and operational efficiency.

Wet processing technology has revolutionized the way materials are handled, processed, and recovered, offering significant advantages over traditional dry processing methods. Our solutions are designed to provide superior washing, classification, and dewatering capabilities. Our clients achieve the highest standards of product purity and operational efficiency.

Key Components of Our Wet Processing Systems

Our wet processing systems incorporate various components engineered to maximize processing efficiency and material recovery:

- High-Pressure Washing Units: Remove dirt, clay, and other impurities from aggregate and mineral materials, enhancing product quality.

- Advanced Classification Systems: Separate materials based on size and density, ensuring precise product specifications.

- Dewatering Screens and Hydrocyclones: Efficiently remove excess water from processed materials, reducing drying time and costs.

- Water Recycling and Sludge Management: Minimize environmental impact and reduce water consumption by recycling process water and managing sludge effectively.

Benefits of Implementing Our Wet Processing Solutions

By integrating our wet processing solutions, businesses can achieve:

- Enhanced Product Quality: Achieve cleaner, higher-quality products that meet stringent industry standards.

- Increased Operational Efficiency: Streamline operations and reduce downtime with highly efficient and reliable systems.

- Environmental Compliance: Meet environmental regulations with advanced water recycling and waste management technologies.

- Cost Savings: Reduce water usage and minimize waste, leading to significant cost reductions over time.

Download the Terex Full Line Brochure

Key Products of Terex Washing Systems

WASHING & CLASSIFYING

Fines material dewatering options.

MODULAR WASH PLANTS

Produce up to 3 washed aggregates and 2 washed sand products simultaneously.

WATER MGT

Remove the need for settling ponds: Flocculant dosing, thickener tanks, filter presses.

SCRUBBING

Aggressive attrition for sticky, high clay content material.

WASH SCREENS

Static, modular and mobile units for sizing and dewatering.

Tailoring Solutions to Industry-Specific Needs

We understand that each industry has unique challenges and requirements. Our team of experts works closely with clients to develop customized wet processing solutions that address specific needs and goals.

- Aggregates: Improve the quality and value of sand and gravel products.

- Mining: Enhance mineral recovery and reduce environmental impact.

- Waste Management and Recycling: Recover valuable materials from waste streams.

- Indigenous and Government Projects: Provide sustainable and efficient processing solutions for community and national projects.

Future-Proof Your Operations with Foreman Equipment

Investing in advanced wet processing technology is not just about upgrading equipment; it’s about enhancing sustainability, and staying ahead of industry trends. At Foreman Equipment, we are committed to providing our clients with state-of-the-art solutions that drive success and innovation.

Conclusion

Embracing advanced wet processing solutions is essential for industries looking to improve efficiency, sustainability, and product quality. At Foreman Equipment, we offer the expertise, technology, and support necessary to achieve these goals. Contact us today to learn how our wet processing solutions can transform your operations and lead to long-term success.

Embrace the Benefits of Wash Recycling

Wash recycling transforms used concrete, sand and aggregates into reusable materials, conserving natural resources and reducing landfill waste. This approach not only contributes to environmental conservation but also saves energy, cuts pollution, and stimulates job growth within the recycling sector.

Transforming waste material into usable aggregate products from demolition can reduce construction costs and even open new revenue streams for producers.

Our wet processing solutions have transformed operations for numerous clients across various industries. By implementing our systems, clients have reported significant improvements in product quality, operational efficiency, and environmental sustainability.

You can recover up to 80% of the waste from Hydro-vac Excavation and turn it into usable, salable sand and rock products. Learn more about Capital City Paving’s Hydrovac Recovery System is helping contractors reduce costs and improve environmental sustainability.

Unlock the potential of your projects with our cutting-edge washing solutions.

Contact Foreman Equipment today to explore the perfect fit for your needs and see how we can support your next project from start to finish.

Email us by filling out the form or calling 1-888-852-9021